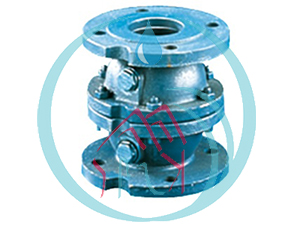

Membrane check valves – 407B boosting units, vacuum pumps, compressed air

PRESSURE PFA/PS in bar θ 60°

CASING : GJL cast iron epoxy coated

447B : length according to EN558-I serie 48

2 threaded bosses 1/2” with brass plug

SEAT : DN40 to 80 : Stainless Steel DN100 to 200 : Polyamid coated steel

SEALS : EPDM – MEMBRANE : NR (natural rubber)

Appication and special features :

- Operates in any position

- Low head loss

- Very silent

- Does not generate hammering

- 2 threaded bosses 1/2″ with brass plug.

- Closing system : flexible membrane (thick elastomer disc) held in its center on a metal seat consisting of a grid (flow equivalent to the minimal section)

- Sealing ensured by self-closing membrane

- On membrane check valves, the opening regulated by the elasticity and the thickness of the membrane is very proggressive and can be obtained as a result of a few centimeters of W/C. Because of this, this check valve is particularly suitable for a varibale flow pumps and pulsatory operation.

| DN | PFA | PS | Cat | Réf. | UV | ||||

| “ | mm | water | L1 | L2 | G1 | G2 | |||

| 11/2 | 40* | 16 | 16 | 16 | 16 | 16 | 1 | 149B 1166 | 1 |

| 2 | 50* | 16 | 16 | 16 | 16 | 16 | 1 | 149B 1167 | 1 |

| 21/4 | 60* | 16 | 16 | 16 | 16 | 16 | 1 | 149B 2163 | 1 |

| 21/2 | 65* | 16 | 16 | 16 | 15 | 16 | 1 | 149B 1168 | 1 |

| 3 | 80* | 16 | 16 | 16 | 12 | 16 | 1 | 149B 1169 | 1 |

| 4 | 100 | 16 | 16 | 16 | 10 | 16 | 1 | 149B 1170 | 1 |

| 5 | 125 | 16 | 16 | 16 | 0.5 | 16 | 1 | 149B 1171 | 1 |

| 6 | 150 | 16 | 13 | 16 | 0.5 | 16 | 1 | 149B 1172 | 1 |

| 8 | 200 | 10 | 10 | 10 | 0.5 | 10 | 1 | 149B 1173 | 1 |